Nadira Kovacevic +49 (0) 7303 - 92874 - 33 kovacevic@ttv-gmbh.de

The construction machinery market is characterised by price wars and a high level of competitive pressure. The outcome of this development is an increase in productivity and increased sustainability due to new types of drives, as well as consumption optimisations. This is clearly demonstrated by the current product developments by leading construction machinery manufacturers.

There is a trend towards mobile construction machinery, with electric drives an increasingly common feature of machinery for use in urban areas. Consumers want “Made in Germany” quality but are simultaneously demanding concrete benefits in terms of quality and performance.

As was also the case the previous year, the European market developed better than the markets in most other regions worldwide. In terms of market growth, Europe is in 3rd place behind China and India. Within Europe, the strongest sales growth was achieved in the French, German and Italian markets.

The construction machinery market is also highly competitive, and is characterised by the typical side effects such as price competition and high levels of competitive pressure. This development in the construction sector requires cost reductions, productivity increases and a reduction in machine consumption, and this is also apparent in the product development work currently being carried out by leading construction machine manufacturers. This trend points to mobile construction machines that are powerful, quiet and highly productive with low fuel consumption. German manufacturers produce machines of recognised Made in Germany quality, but are under increasing pressure to tangibly demonstrate their quality and performance benefits in the form of profitability comparisons.

The range of different products used in construction machinery technology is huge. These products range from compact excavators and chain excavators to compaction machines, wheel loaders, tracked carriers and telehandlers right through to asphalt millers and wheeled pavers such as those used for asphalt installation on extreme inclines of up to 11%, which is quite common in the Alps.

This wide variety of products and the high stresses put on the hydraulics, engines, transmissions and all moving parts mean that both machine manufacturers and suppliers need to be able to provide components and assemblies of reliably high quality.

High levels of competitive pressure, extremely high technical requirements and the industry's desire for differentiation all mean that components are increasingly being developed to be both customer and product-specific. The reasons for this are clear. Standard products are usually available immediately, but rarely achieve the right balance between verifiably long service lives, innovative strength and competitive advantages. This trend towards individual product solutions is met by ttv in the form of its own dedicated development area.

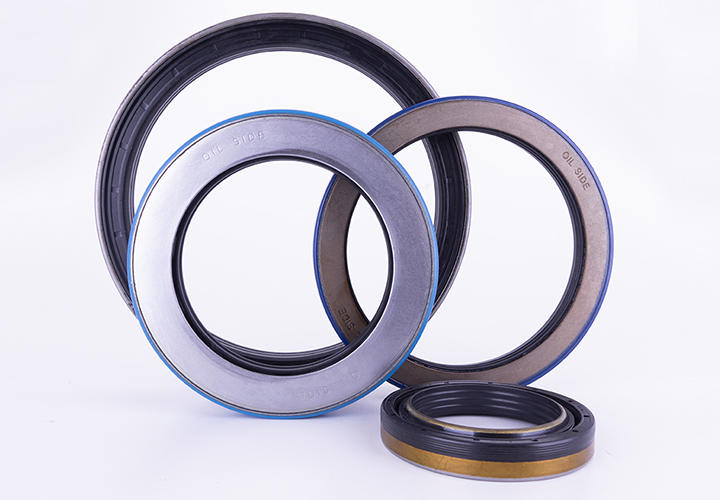

Over recent years, ttv has established itself as a specialist in construction machine technology as well as in agricultural engineering, with its two competence fields of seals and slide bushings. For ttv, typical challenges include applications relating to drive trains, transmission gearing, ring gear seals and axles. Customers usually have a very clear profile made up of previous experience and objectives. Standard products from stock are often not adequate in dealing with the enormous strains experienced in the construction sector, such as continual use in mud, heat, frost or wet conditions. The increasing time constraints also lead to a significant increase in the amount of strain being put on the materials.

This development has lead to the strategic decision by ttv to set up a separate development area for customer-specific product solutions, with substantial capacity to support ttv customers. ttv has an experienced team of specialists in the fields of technology and engineering working in this new area, and these specialists, who are based in Illertissen, Germany, attend to every conceivable detail of a project. Material properties, material composition and design open up possibilities to increase performance, thereby ensuring that dirt, mud and moisture remain on the outside.

In the field of technological components and assemblies, seals and sliding bushings are only a comparatively small component. But this should not hide the fact that both product categories are often decisive for the service life and functionality of construction machinery and construction vehicles.

Customer and project-specific solutions from ttv have demonstrably led to a significant increase in service life, temperature resistance, friction properties and tightness in recent years.

Mounted in a split housing, the ttv drive seals are pressed against each other with their lapped running surfaces. As a rule, an O-ring (NBR / FPM / etc.) serves as a pretensioning element which fixes and aligns the seal in the housing. Since the entry of aggressive and abrasive media into the seal is prevented, the high wear resistance and service life could be guaranteed.

A solution for every current requirement.

Branche

Construction machinery and cranes

Problem

Worn sealing ring due to increased friction forces and frictional heat.

Projekt

To modify the design and geometry in order in improve the wear behaviour due to increased friction forces and frictional heat.

Usage

Drives on winches and free-fall winch drives.

Requirements

Increasingly fast-running winches and free-fall winches bring about higher circumferential speeds, temperatures and friction levels. The resulting wear pattern on the FPM shaft sealing rings needs to be significantly and sustainably improved. The general standard design currently in use was also checked and optimised. Pressure peaks that sometimes occur, as well as the application-specific parameters (speed, temperature, direction of rotation etc.) form the technical starting point.

A high level of leak-tightness combined with minimal friction are the most important requirements here.

Approach/Running test

Gradual step-by-step approach by changing the spring length and diameter and correcting the membrane of the shaft sealing ring. Close observation and analysis of the membrane by means of pressurisation and after checking the wear track in order to prevent sagging as a result of the pressure. Comparison of the spring effect and the membrane/suspension via pressure load cell and subsequent trialling in running test.

Test bench runs and testing carried out in multiple steps on the whole unit at the customer's premises ultimately lead to an optimal geometry correction.

Result

Thanks to the use of the improved LF (low friction) shaft sealing rings in FPM, it was possible to meet our customer's more demanding usage conditions. The optimal balance between contact pressure and leak-tightness was achieved thanks to the close collaboration between technology and development over the course of six months.

Advantage

Friction behaviour improvement of 18.5 %.